B820

The vision system is located under the conveyor, which is mainly used for optical inspection of products welded after DIP wave peak welding

Below On-Line AOI

Flexible/Multi-function AOI

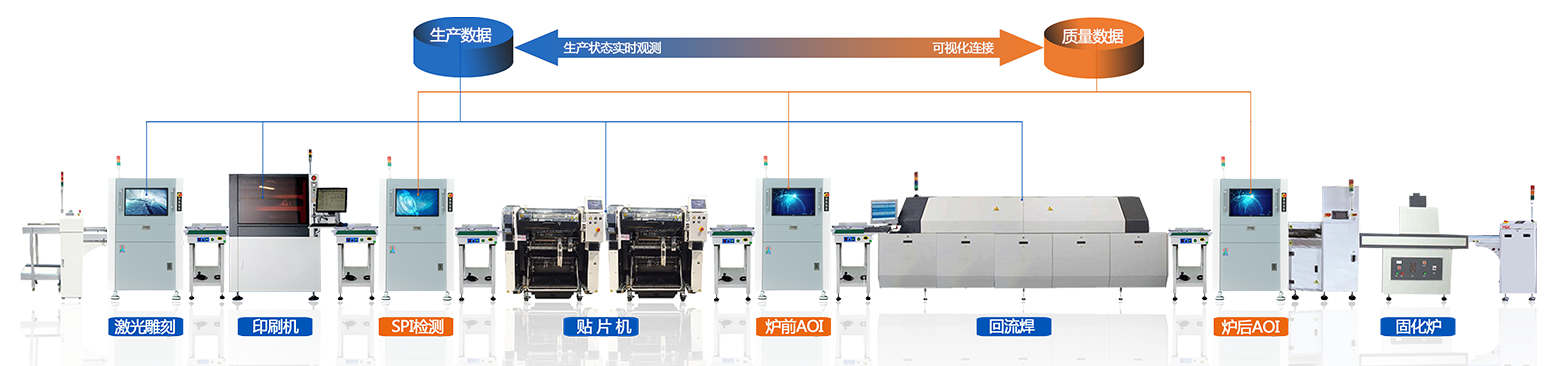

It can be placed at several quality controlling points in SMT Line to check 2D paste printing quality, inspect component defects before reflow soldering, inspect PCBA quality after reflip soldering and DIP wave soldering.

Germany imported 5-megapixel high-speed industrial camera

With extremely high color reproduction effect, coupled with high-resolution high-profile far-reaching heart lens, the product has high poor recognition, providing high-definition image output for AOI devices.

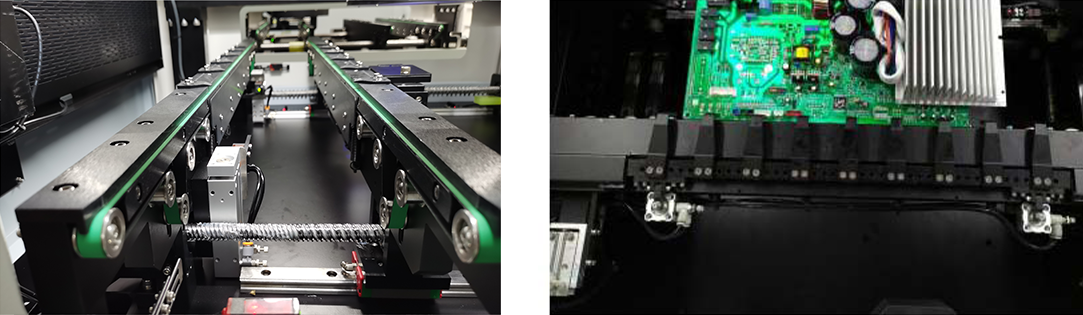

Belt drive

double motor design, faster transmission, can carry heavier products

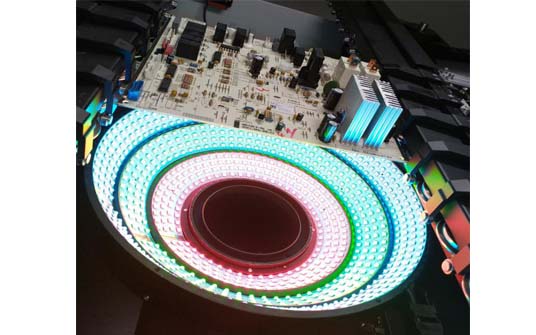

Self-developed ultra-large R/G/B/W light source

no dead Angle irradiation 360 degrees, so that there is no place to hide bad components & solder joints

Full vector algorithm

Fusion logic operation, for wave soldering pin, tin hole and bridge, more simple and stable

Consumer protection service items usually include "free warranty maintenance",

"regular return visit", "on-site training", "24-hour appeal response" and other

categories. We provide customers with the best equipment and perfect fast

service guarantee with the most sincere attitude.

● The equipment shall be guaranteed free of charge for one year and maintained

for life from the date of acceptance. The operationcontrol software of the sold

equipment shall be upgraded free of charge for life to ensure the latest software

version and optimization of functions.

● Call back and visit customers irregularly, communicate with customers in time

and improve relevant problems.

● The Customer Service Department shall respond to customer demands within

24 hours and within 2 hours after receiving them.

Overseas customers can provide nearby technical services or provide remote

training and technical support according to actual needs.